Designing a Winning Order Fulfilment Workflow

Do you find yourself caught in the web of order fulfilment challenges, wondering why your stellar marketing efforts sometimes fall short?

If so, you're not alone. Many online retailers have to deal with the dreaded scenario of customers who tried to place an order, but had a less-than-ideal experience. The ripple effect? Their future loyalty hangs in the balance.

No matter how flashy your marketing campaigns are, if your order fulfilment isn't up to snuff, you're missing the mark. Which is why designing a winning order fulfilment workflow is high on any online retailer's to-do list.

You have to craft an experience that keeps customers coming back for more. You want them to be wowed, not worried about when their package will arrive!

In this blogspot, we will unravel the secrets behind a seamless order fulfilment workflow. From ironing out potential pitfalls to streamlining the journey from warehouse to doorstep, we've got you covered.

Your journey to a more efficient, customer-centric e-commerce operation starts right here.

Demystifying Order Fulfilment

Order fulfilment is the journey an order embarks on from the moment a customer clicks 'purchase' to the exciting delivery at their doorstep.

But order fulfilment is not just about dispatching parcels—we need to consider the possibility that, at times, customers might not be thrilled with their purchase. Yes, returns are part of the game.

True success is not just in getting the order to their doorstep—it's making sure everything runs seamlessly from sale to delivery.

The Receiving Phase in Order Fulfilment

Now, let's look at the first step of the order fulfilment process: the receiving phase. This is the step that sets the stage for the whole process to come.

The order fulfilment process starts when fresh inventory from suppliers and manufacturers is delivered at your warehouse. Which means you have to meticulously count each item, ensuring what's in the boxes matches your order. No damaged goods should sneak past your watchful eye – it's quality control in action.

But the work doesn't stop there. Data takes the spotlight as you input crucial information into your warehouse management software. Location, counts, and sales numbers – every detail matters. If items lack the appropriate labels, no worries—SKUs and barcodes are added, and individual items may even come together in ready-to-ship kit packages.

With the inventory accounted for, it's time to find its place in the warehouse. Think of it like organising a library – each SKU has its own spot, with overflow neatly stored in another section.

The receiving phase sets the tone for the whole process to follow. Every item, every count, and every detail matters—and will have an effect down the line.

The Processing Phase of Order Fulfilment

Now, let's look at the next step, which is the beating heart of order fulfilment – the processing phase. It's the moment a customer order is received and the real action begins.

When a customer clicks on the 'buy' button, the order lands in your fulfilment warehouse thanks to seamless integration between fulfilment and shopping cart software.

Someone working in the warehouse will then head to the shelves to pick out each item with care and take them to the packing area. It's not just about speed of execution—it's about quality. Each item is scrutinised, ensuring it meets the mark.

Packaging materials are carefully selected for each item. Packing slips and extras are added for that personal touch, and with a flourish, the box is sealed and ready for its grand exit. Now the package is ready to be delivered.

The Delivery Phase of Order Fulfilment

And now we get to the final stage—the delivery phase when your customer's purchase arrives at their doorstep.

The order takes centre stage at the shipping station, the hub where the final touches are added before the grand send-off. The package is weighed, and the optimal shipping method is selected, ensuring a smooth journey from your warehouse to the customer's hands.

The shipping station will also assign the best courier for the job. Whether it's the national postal service or a major player like UPS, FedEx, or DHL, the goal is a flawless delivery performance.

Once the package leaves the shipping station, the order status of the package will be updated, allowing customers to track their purchases in real-time.

Once the package arrives at its destination, the order is officially fulfilled.

The Often Overlooked Returns Processing Step

In the order fulfilment workflow, there's a less glamorous but equally vital last step – the returns processing.

Customers usually have a window to send products back, whether for a refund or replacement, depending on your policies.

Unfortunately for the retailer, returns can easily send you back to square one. If the item is defective or suffered a blow during transit, replacement orders need to be initiated, and your suppliers should be in the loop if their product was defective.

Organisation is key to make the returns process work. Proper labels, correct shelving, and meticulous computer entries ensure nothing goes astray.

Your business is unique — your software should be too. Let's talk about a system built around how you actually work.

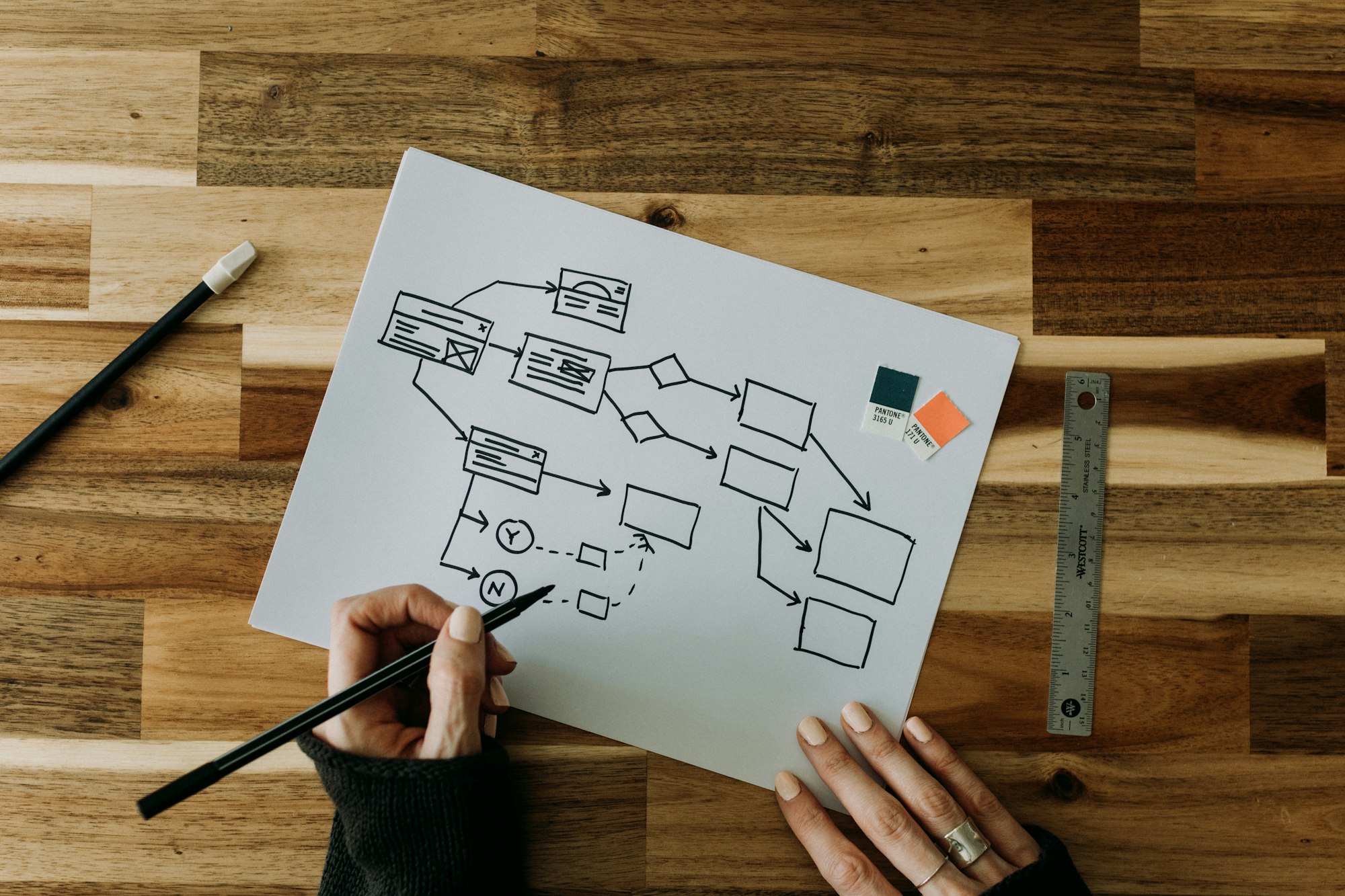

Book a free consultationDelving Into the Specifics of your Workflow Design

Now we will look at specific considerations when crafting the blueprint for your optimal order fulfilment workflow:

1. Tailoring Your Order Fulfilment to Company Size and Volume

When it comes to your order fulfilment workflow, the first step is understanding the specifics of your company – its size and the volume of orders it will have to process each month.

Begin by asking: How many orders does your company handle monthly, and, equally crucial, how many can you ship out within that same timeframe? This sets the baseline for your operations.

But don't stop there – envision the future. How many orders do you expect to receive and ship out over the next few months, and even the coming year?

There's no one-size-fits-all solution. Each company has its unique requirements, and understanding your current operations is the key to finding the right order fulfilment strategy.

2. Aligning Order Fulfilment with Sales and Technology

The second factor to fine-tune is the harmony between your sales channels and current technology.

Begin by examining your sales channels. How does your company promote and sell products? Are you navigating the e-commerce landscape with a specific platform, or perhaps leveraging the dual power of a business website and online marketplaces? Many companies blend these channels to cast a wide net, reaching the broadest audience possible.

Now, let's talk about tech. With the right order fulfilment software, you can weave your existing platforms into a cohesive whole. It's important that all the different software platforms integrate seamlessly when processing and tracking orders.

But here's the caveat – simplicity is key. The ideal solution doesn't complicate your order fulfilment—instead, it simplifies the process.

3. Customer Location as a Key Factor in Order Fulfilment

The third factor to consider is the geographical map of your customer base.

Start by examining where the majority of your orders are coming from. Is your customer base primarily local, or does it span across international borders? This geographical insight becomes the compass guiding your choice of fulfilment software, ensuring you can navigate the terrain efficiently.

Why does it matter? Speed is the name of the game. You want to meet customer expectations by getting orders to them swiftly.

Even within domestic borders, challenges can arise. Consider this – sending a package to a rural area may incur higher shipping costs compared to an urban destination.

Best Practices for Seamless Order Fulfilment

When it comes to crafting an order fulfilment workflow, getting it right involves not just crafting the perfect model, but adopting best practices that will elevate the entire process.

First and foremost, find a platform that flexes and adapts to your unique fulfilment strategy. The ideal workflow software should harness data effectively, creating real-time predictions to guide inventory decisions and enhance demand forecasts.

Now, let's talk about process automation. The goal of workflow automation is making the fulfilment process efficient while sparing your employees from unnecessary manual labour. You can use automation to create a system where tasks seamlessly flow from one stage to another, like a perfectly choreographed dance routine.

Craft a model that fits, find a platform that adapts, and let automation take centre stage.

Navigating Common Hurdles in Order Fulfilment

Challenges often emerge in your order fulfilment process, testing the resilience of your operations.

Most frequently, these hurdles take the form of inventory management hiccups and structural issues within a company's business processes:

You shouldn't need to find workarounds.

Let's build the software so you won't have to.

1. The Challenge of Incorrectly Filled Orders in Order Fulfilment

Incorrectly filled orders can trigger a domino effect, causing dissatisfaction among vendors and customers alike.

One misstep, such as inputting an incorrect SKU number, can disrupt the whole system. Addressing this issue requires meticulous attention to detail in data entry and order processing.

In the hustle of the warehouse, a worker might unwittingly introduce an unplanned twist by placing the wrong item in a package. This challenge underscores the importance of robust quality control measures and a well-organised storage system.

The solution to both these problems is implementing rigorous quality checks at various stages of the order fulfilment process.

Arm your team with thorough training to enhance their awareness of the critical role they play. Emphasise the importance of double-checking SKU numbers and the contents of each package before sealing the deal.

Leverage technology to your advantage. Barcode scanning systems and order verification software can catch any discrepancies before the wrong package leaves the warehouse.

2. Overcoming the Challenge of Stockouts in Order Fulfilment

Stockouts is a serious problem for online retailers. When a customer clicks 'buy,' they envision the joy of receiving the product they desire. A stockout shatters this expectation, leaving them disheartened.

The solution is to implement robust demand forecasting practices. Analyse historical data, track trends, and leverage predictive analytics to anticipate demand accurately. This strategic foresight ensures you're prepared for peaks and valleys in customer orders.

Introduce safety stock measures as a buffer against unexpected surges in demand or supply chain disruptions. This safety net cushions the impact of stockouts, allowing you to meet customer expectations even during unforeseen challenges.

Embrace technology that offers real-time inventory tracking. This allows you to monitor stock levels continuously and swiftly respond to fluctuations.

Foster strong relationships with your suppliers. Open lines of communication and collaborate closely to ensure a steady and reliable supply chain. When you're in sync with your suppliers, the risk of stockouts diminishes.

3. Addressing the Challenge of Packing Delays in Order Fulfilment

Once an order is in, the countdown begins. Retrieving an item from the inventory and packaging it for shipping requires precision timing. If a worker struggles to locate an item or the packing process lacks efficiency, it causes delays that can disappoint eager customers.

The solution is to design your inventory layout for easy navigation. Keep frequently ordered items within reach of packing stations to reduce retrieval time. An organised warehouse is the foundation for an efficient packing process.

Implement barcode systems and automation tools to streamline the packing process. Barcode scanning ensures accurate item retrieval, and automation reduces manual handling, enhancing overall efficiency.

Train your team comprehensively on the packing process. Provide clear guidelines on item locations, packing procedures, and troubleshooting strategies. A well-trained team is instrumental in maintaining a smooth and timely workflow.

Regularly evaluate your packing process for bottlenecks and inefficiencies. Identify areas where delays commonly occur and implement improvements.

4. Confronting the Challenge of Overseas Shipping in Order Fulfilment

Sending a package overseas requires special care. While it expands your reach, it introduces complexities that can impact delivery times, incur additional costs, and necessitate careful consideration of customs procedures. It's a challenge that requires a global mindset.

When it comes to shipping internationally, clearly communicate shipping timelines to customers. Managing expectations is crucial, especially when international delivery can vary significantly depending on the destination. Transparency builds trust and understanding.

Master the art of customs documentation. Provide accurate and detailed information on packages to facilitate smooth customs clearance. This not only expedites the shipping process but also helps in avoiding unnecessary delays and fees.

Account for additional costs upfront. Whether it's customs fees, taxes, or shipping charges, transparently communicate these to customers during the checkout process. No one likes surprises, especially when it comes to their order total.

Develop a robust process for international returns. Consider the intricacies of different exchange rates and customs regulations. Offering replacements or refunds in a manner that aligns with international standards ensures a positive customer experience.

5. Tackling the Challenge of Communication Breakdowns in Order Fulfilment

Order fulfilment relies on a well-coordinated team – from suppliers and internal teams to customers. Any disruption in communication can lead to misunderstandings, delays, and, ultimately, process breakdown.

It's paramount to foster open lines of communication with suppliers. Regular updates on stock availability, potential delays, and other pertinent information ensure that you're well-informed to meet customer demand.

Equally important is to establish clear channels for customer communication. Respond promptly to concerns, queries, and feedback. A transparent and customer-centric approach builds trust and loyalty.

Finally, implement robust internal communication platforms within your company. Whether it's through messaging systems, regular meetings, or project management tools, creating avenues for team members to communicate prevents bottlenecks and promotes a smooth workflow.

To aid you in your communication efforts, leverage automation for real-time updates. Automated notifications can keep all stakeholders in the loop, from order confirmations to shipping details, reducing the chances of missed information.

In the event of an issue, adopt a proactive approach. Swiftly address concerns, keep all parties informed, and offer solutions.

Conclusion

In the fast-paced world of business, time is money. If you're looking to save time, boost customer satisfaction, and amp up your profitability, one effective strategy is streamlining your order fulfilment process.

First off, it's crucial to understand the different functions involved in order fulfilment. We're talking about the nitty-gritty tasks that make sure your product goes from point A to point B smoothly. From picking and packing to shipping, each step matters.

And guess what? You can tweak and optimise each of these functions to make everything run like a well-oiled machine.

Now, for the small business owners out there, keeping these operations in-house might be doable. It gives you control, and who doesn't love that? On the flip side, if you're running a bigger operation, you might need to loosen the reins a bit. Yep, that means taking on a bit more risk to get those orders out efficiently.

But here's the key – whether you're steering a small ship or captaining a massive fleet, research is your best mate. Dive deep into the specifics of your business, understand its unique requirements, and choose the order fulfilment option that fits like a glove.

And as is true with most things in life, success is not just a destination but a continuous journey of refinement, adaptation, and discovery.

An effective order fulfilment strategy is the key to better service, happier customers and a fatter bottom line. So, what are you waiting for? Now is the time to take your company's operations to the next level.